Shore connections + LNG ships: a technical challenge around “boil-off gas”

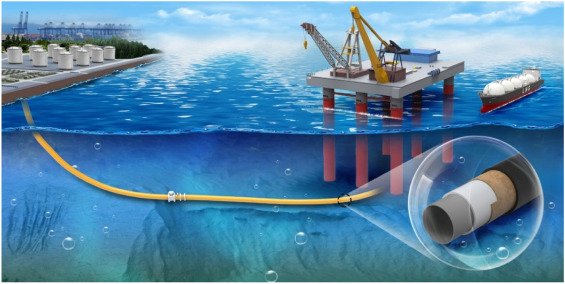

Two priorities of maritime decarbonization can come into tension when a ship arrives at port: on one hand, shore power (cold ironing / OPS) to shut down engines and reduce local emissions; on the other hand, the use of LNG as fuel. The point of friction? The management of “boil-off gas” (BOG), this gas that naturally evaporates in LNG tanks and must be controlled to prevent any pressure buildup.

A technical report highlights an operational risk: when a ship docks, it reduces or stops certain systems that usually consume this gas (engines, generators). Result: BOG can accumulate faster, especially on certain tank configurations that are less pressure-tolerant. Some technologies, such as dual-fuel boilers, allow this gas to be burned even at the dock, but this can also result in inefficient energy use (more gas burned than necessary).

The most problematic scenario remains the ventilation of BOG, to be avoided as much as possible: methane has a very high climate impact, and this option is only considered in emergency situations. The recommendations therefore emphasize the sharing of operational experience, the optimization of dock procedures, and a pragmatic regulatory approach for older ships, without creating a competitive advantage for those who cannot fully comply.

The post Shore connections + LNG ships: a technical challenge around “boil-off gas” appeared first on The Logistic News.

Share this post

Related

Posts

Shore connections + LNG ships: a technical challenge around “boil-off gas”

Two priorities of maritime decarbonization can come into tension when a ship arrives at port: on one hand, shore power...

Reverse relocation: industrialists return to produce in China, driven by congestion and lack of capacity

After several waves of relocation to Southeast Asia, an unexpected movement is resurfacing: some productions are returning… to China. In...

Tension in the Strait of Hormuz: Iranian speedboats threaten to intercept the tanker Stena Imperative

New episode of nervousness in one of the most sensitive maritime passages in the world: an American-flagged tanker, Stena Imperative,...

ICTSI: Contecon Manzanillo exceeds 12 million TEUs since 2013

On the Pacific coast of Mexico, the subsidiary Contecon Manzanillo — operated by ICTSI — crossed a symbolic bar: more...